Medium is a material made from softwood fibres, such as conifers.

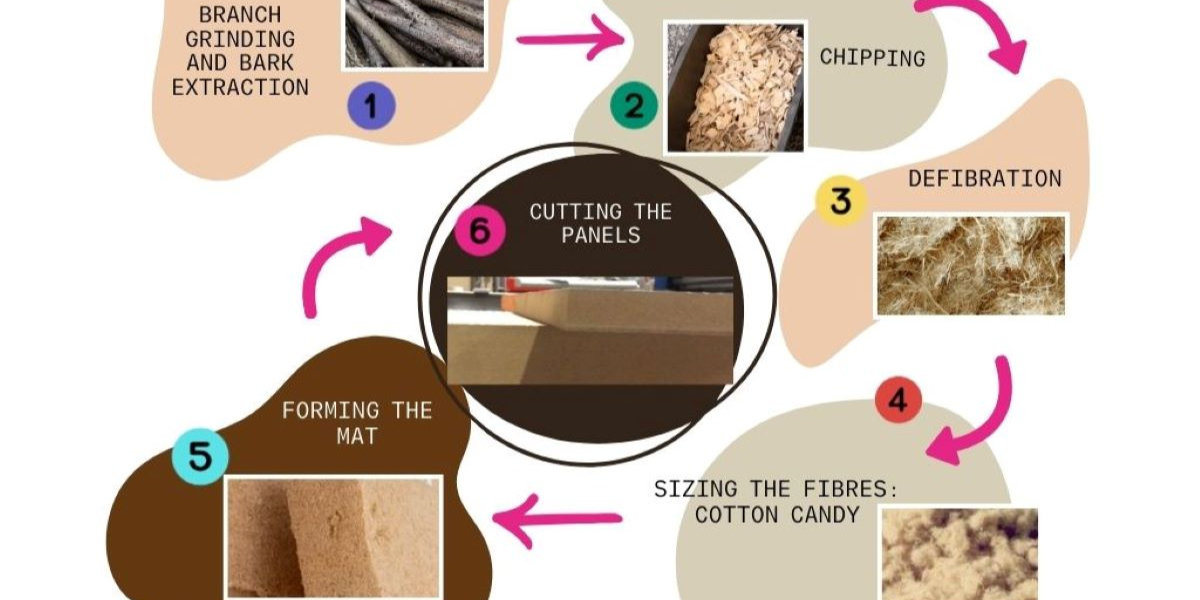

1-Branch grinding and bark extraction

The branches are first passed through a drum to remove the bark.

2-Chipping

The branches are then chipped, the different sizes of chippings are sieved and separated, and the large chippings are reground in order to keep the chippings homogeneous. The shavings are washed and cleaned of dust.

3-Defibration

The chips then undergo a steam defibration operation, the heat helping to release the wood fibres.

4-Sizing the fibres: cotton candy

The fibres are dried so that they can be mixed with a sticky material and hot air to obtain the desired moisture content to form a ‘candyfloss’ type texture.

5- Forming the mat

These ‘cotton candy balls’ are then placed in a mould to form a mattress and pre-pressed to remove as much air as possible.

6-Cutting the panels

The now more compact mattress is then passed through a heat press to complete the panel formation. The size of the panel can vary from 3 mm to a maximum of 50 mm, with 40 and 50 mm not being available from all suppliers.

The advantages and disadvantages of fibreboard

MDF is easy to work with. It does not break. If a lacquer finish is required, a primer is added to the panel so that the lacquer remains even and spreads perfectly over the smooth surface created by the fibre.

It is often used as a base for laminate, where a sheet of laminate is glued to each side to create a compact, strong sandwich. You can also put a sheet of laminate on one side and a counter-balancing sheet on the other to keep the panel straight and uniform on both sides.

It can be treated with a product that makes it water- or fire-repellent.

However, MDF's main weakness is its sensitivity to water. Under no circumstances should it come into direct contact with the rain. It should therefore only be used indoors. Similarly, if it is used in a damp room such as a bathroom, it is preferable to treat it with a water-repellent treatment beforehand.

The compact characteristics of MDF make it heavier than plywood or chipboard, but it is still easier to handle than solid wood.